David Llodrá, Research & Development Director

Oak Solutions Group

ABSTRACT

An experiment with products of the same toast but different particle size (large chips, cubes and tank staves) and at two dose rates (3 g/L and 9 g/L) was conducted to evaluate the importance of each factor. The results demonstrated that balanced extractions will be achieved at different contact times depending on particle size (chips extract faster than cubes, which extract faster than tank staves).

The similarity in aroma perception and chemical composition of wines made with cubes at shorter contact times and tank staves for longer times suggests that cubes can replace the use of tank staves when time is limited. For maximum levels of aromatic attributes in wine, high dose rate and short contact time work well, and the oak alternatives should be used only once for this purpose. A second use is possible in another wine at a low dose rate for a longer time with the objective of adding complexity through less overall oak impact.

INTRODUCTION

The extraction process of oak products by alcoholic beverages follows several steps until the equilibrium is reached. Before extraction begins, there are higher concentrations of certain compounds on the surface of the oak product (example: furfural), while other compounds are more abundant in the core of the wood (example: tannins). The presence of each compound in wine then changes with time depending on the sorption rate of the liquid in the wood. Ambient conditions will affect the rate of sorption and in consequence, the rate of extraction.

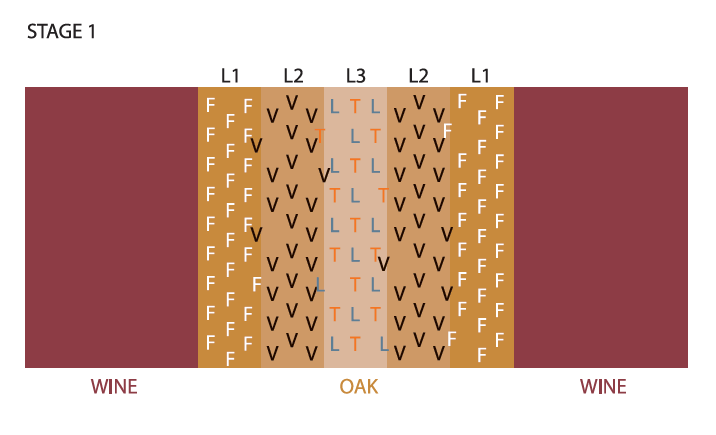

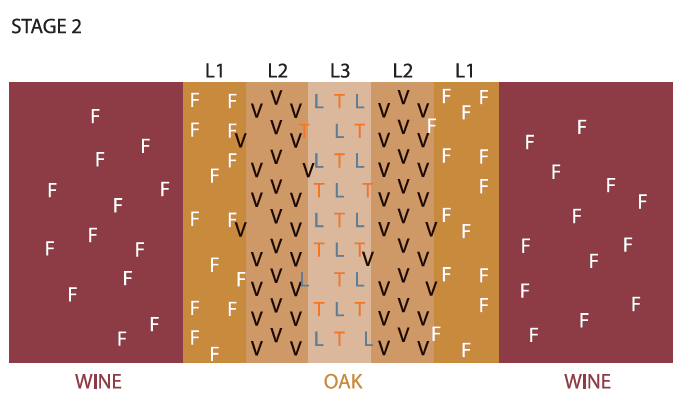

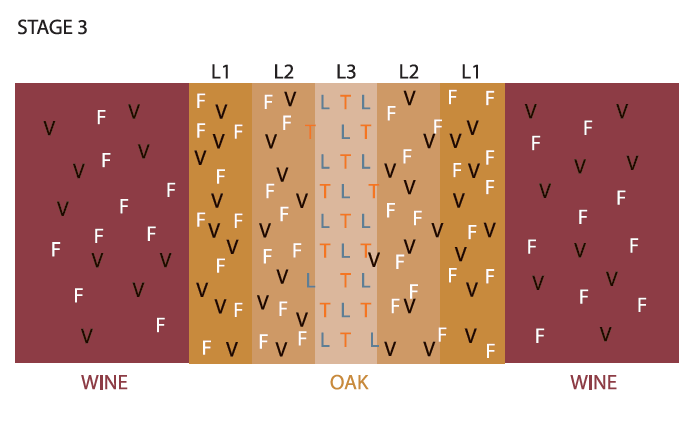

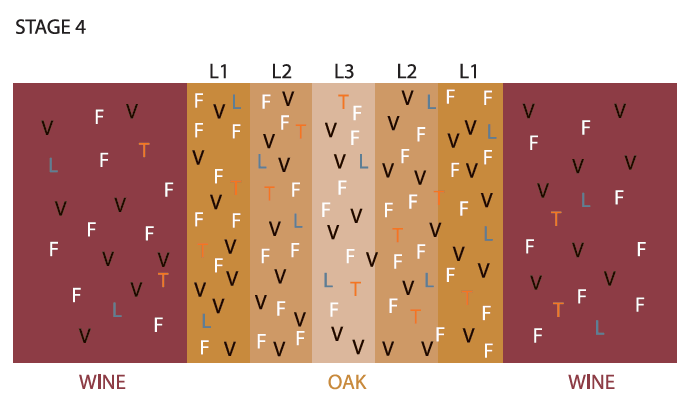

Until sorption of wine reaches equilibrium, chemical compounds in wine will go up or down. The affinity of chemical compounds to the solvent will affect extraction rates (example: vanillin has affinity to ethanol, so a faster extraction will occur in high alcoholic beverages). Figures 1 illustrates the extraction process by taking the example of a tank stave toasted by infrared heat. If an estimation is made that furfural tends to be more abundant on the surface of the oak product, vanillin is more abundant in the layer just behind the toasted surface, and the deeper layers will be richer in tannins and oak lactones, we can assume a progression of extraction affected by the sorption rate as shown in the figures. The last image representing Stage 4 shows what the final equilibrium will look like, when the liquid has reached the core of the stave and enough time has been allowed or mixing has happened to achieve diffusion in the whole liquid, and in consequence, the equilibrium.

Figure 1. Note: L1 is considered the first 2 mm layer from the toasted side, L2 is the 2mm layer just below L1, and L3 is the core 2 mm layer in the center of a 10 mm thick tank stave. V: vanillin; F: furfural; L: oak lactones; & T: tannins.

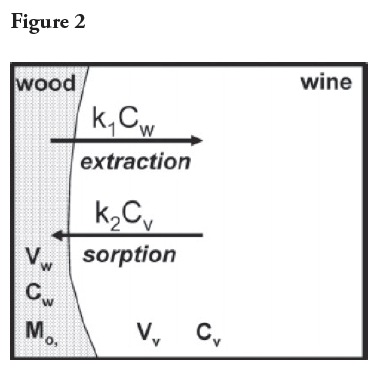

Even without knowing the potential concentration of extractives present in an oak alternative product, it is obvious there are several steps prior to achieving the total equilibrium of oak extraction in a wine. A paper by Dr. Vicente Ferreira serves as a reference for how this process plays out in barrels. Dr. Vicente Ferreira makes reference to the kinetics of aroma extraction and explains the physical process of extraction and sorption as shown in the image from his research paper: “Physicochemical Model to Interpret the Kinetics of Aroma Extraction during Wine Aging in Wood. Model Limitations Suggest the Necessary Existence of Biochemical Processes. Vicente Ferreira, Idoia Jarauta, and Juan Cacho. J. Agric. Food Chem., 2006, 54 (8), 3047-3054”.

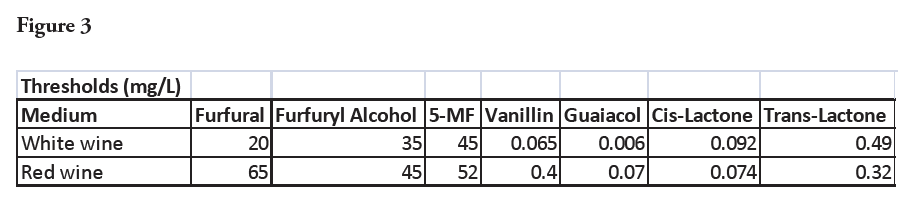

It is essential to perform chemical and sensory analyses, as both are important to understand the impact of toasted oak in wine. Therefore, it is also important to understand the sensory thresholds for chemical compounds that we identify as chemical markers, as the chemical analysis does not give the entire explanation of oak impact. The thresholds of the main chemical markers are listed below for white and red wine.

EXPERIMENTS

In some markets, tank staves have been used for extended periods of time, perhaps inspired by the long aging periods often employed when using barrels. Since it is understood that the extraction rates of tank staves are faster than those of barrels, there was a need to consider if there was a benefit to aging for so long. The European market is known for the tradition of long aging periods, and it is also a market where this question has come up often. For this reason, an experiment was designed and conducted in the Bordeaux area. The experimental parameters are listed below, followed by a discussion of the results.

COMMERCIAL EXPERIMENT

with Merlot, Vintage 2011 from Bordeaux

French oak tank stave treatments (heat source in brackets): abbreviation as shown in graphs

- High Mocha (Convection): HM

- Latitude 44° (Infrared): L44

- High Vanilla (Convection): HV

- FO Convection M+ (Convection): Con

- Cuvée 3 (Infrared): C3

- Latitude 46° (Infrared): L46

- High Spice (Convection): HS

Samples were pulled every three months for eighteen months for

sensory and chemical analyses.

The tastings were based on the following six attributes on a number

scale from 1-7:

a) Fruit

b) Complexity

c) Oak Impact

d) Mouthfeel

e) Structure

f) Oak Balance (Preference)

Results and Discussion

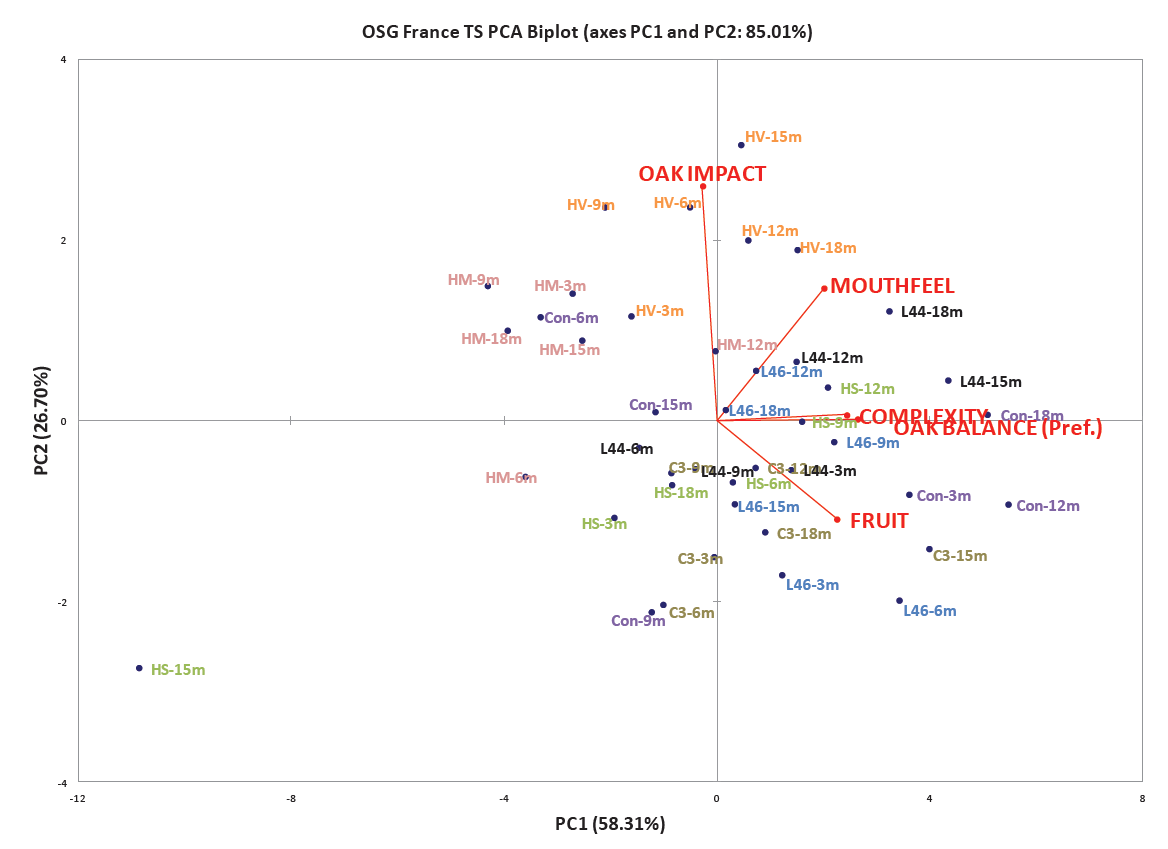

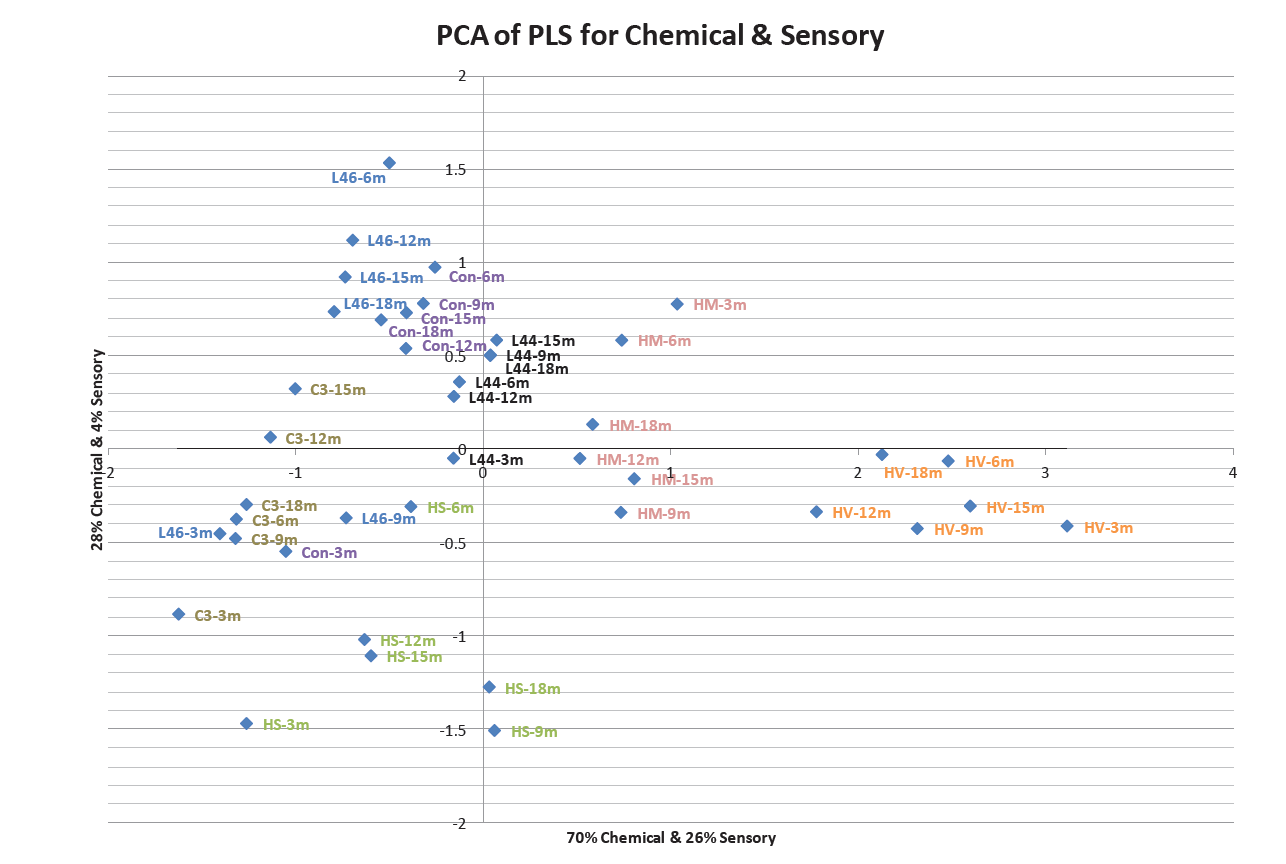

Principal Components Analysis (PCA) is a variable-reduction technique to bring a larger set of variables into a smaller set of ‘artificial’ variables, called ‘Principal Components,’ which account for most of the variance in the original variables. The means of the samples are plotted as Points and the attributes or variables are plotted as Vectors. Left or right placement on the plot is determined by the effect of the variables on the samples, and PC1 explains the variance in that direction. Vertical placement on the plot is explained by PC2, showing the variance in that direction.

The Principal Component Analysis (PCA) shown in Figure 4 is from the sensory descriptive analysis conducted for the Merlot experiment with different tank staves. The results show the toast type created more differentiation than the contact time. Two samples also had the greatest overall oak impact: High Vanilla and High Mocha. Both of these tank staves are toasted by convection for a long time, creating more aromatics than the tank staves toasted by infrared or convection at lower temperatures or for a shorter duration.

Figure 4. Note: Each type of tank stave is color coded for easier interpretation of the graph, and the abbreviation of the product is followed bythe contact time.

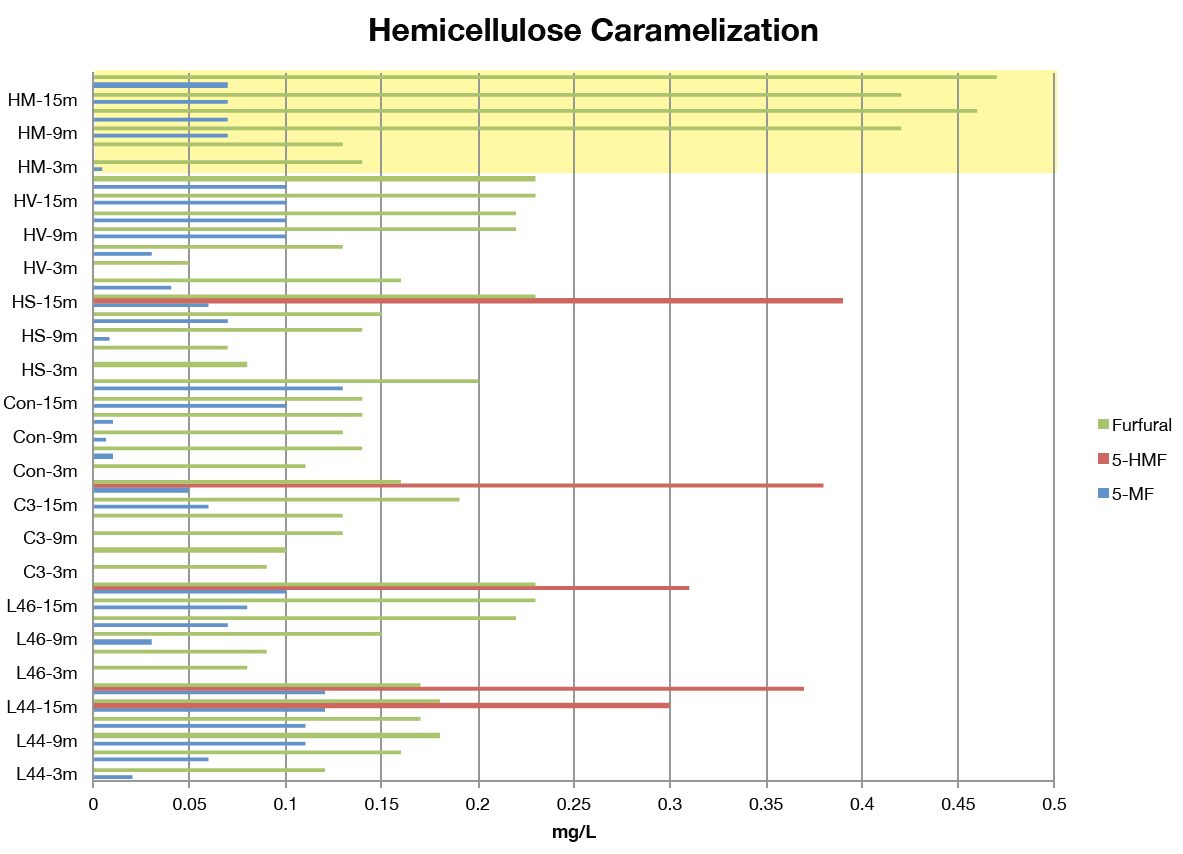

High Mocha tank staves have a higher level of furfural than the other products in the experiment, as shown in the chemical analysis graph (Figure 5).

Figure 5

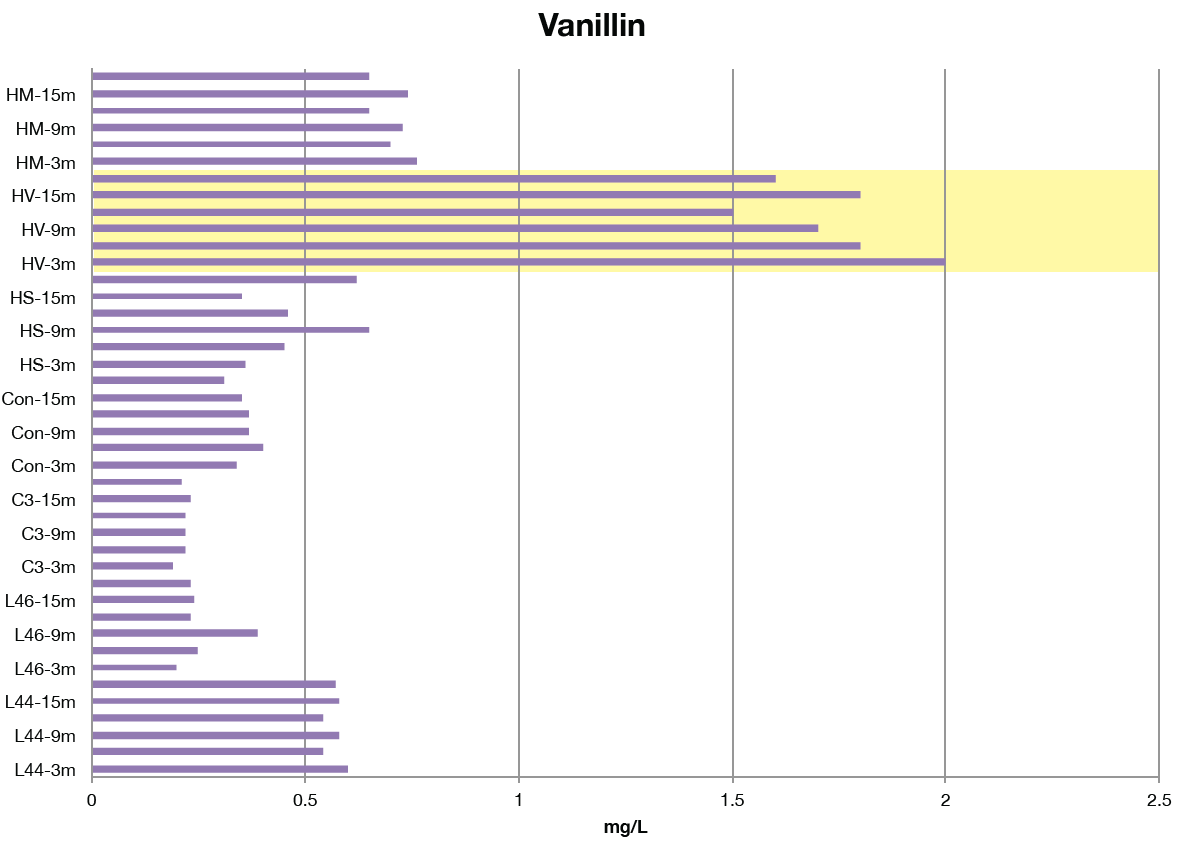

High Vanilla tank staves (HV) contain far more vanillin than all the other products, as these tank staves have been produced following a toasting process to allow the formation of more than double the amount of vanillin than the other tank staves.

Figure 6

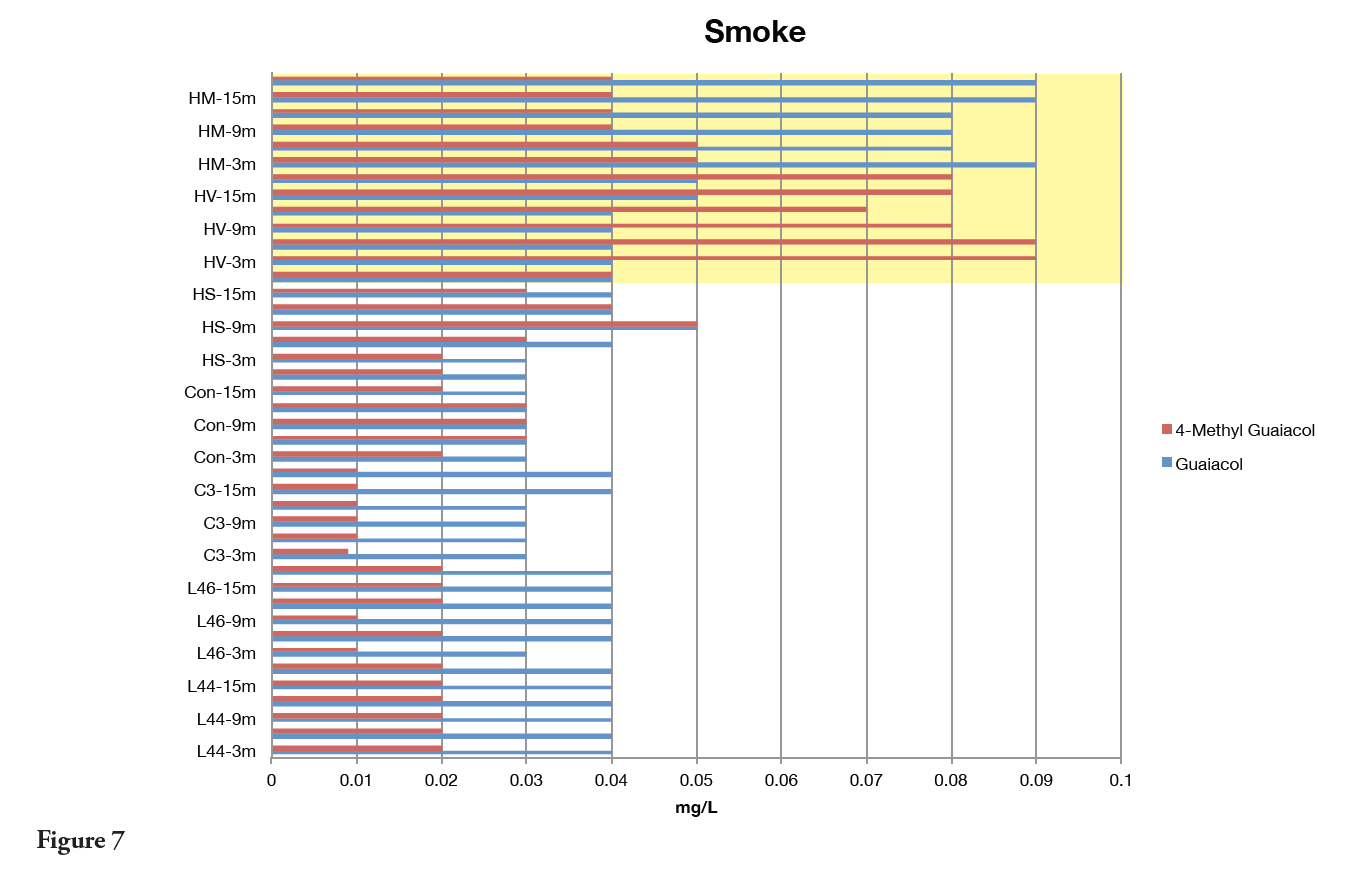

Smoke volatile phenols are extracted very early in the process and are mostly maintained throughout the aging period. Higher levels of phenols are expected in these two products due to toasting recipes that allow for more significant lignin degradation.

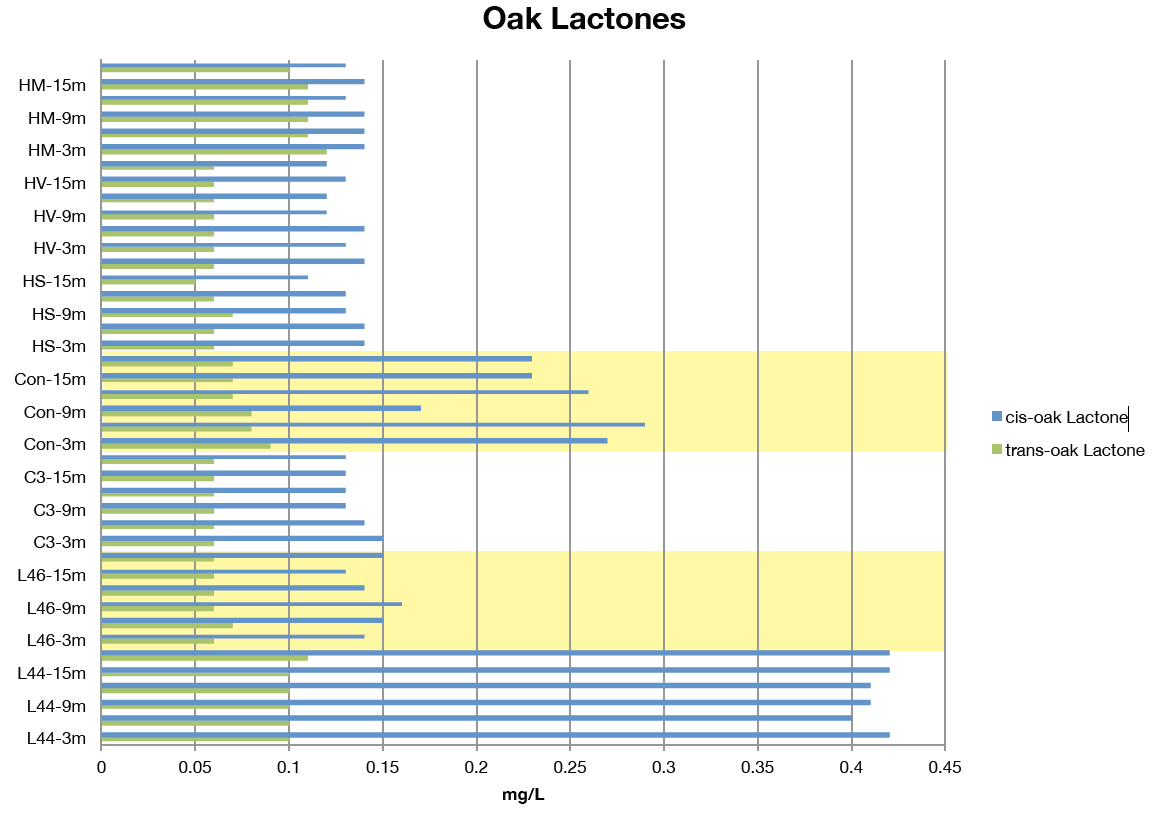

Oak lactones are affected by long toasts more than shorter toasts. For this reason, Latitude 44° and Classic Convection tank staves show higher levels of oak lactones than the other products; their toasting recipes apply less energy overall. This result is consistent at 3 months, 9 months and 15 months.

Figure 8

Figure 9

The principal component analysis of the partial least squares for chemical and sensory in Figure 9 shows the overlap of the two data sets, chemical and sensory. The results indicate the toasting process is more important than the contact time when differentiating between samples. The High Extract products, such as High Mocha and High Vanilla, are in a different location in the plot because of their higher levels of specific chemical compounds, as it has been shown previously, and their intense sensory impact. The rest of the samples show less differences among them, and the infrared toasted products tend to be in the same quadrant.

Conclusions

Each compound has different affinity to the solvent and is concentrated at different depths within the oak product, so maximum extraction will depend on location in the wood product and sorption rates of the liquid. Equilibrium for each compound will be achieved at different contact times depending on the toasting method employed when crafting the oak alternative product. The toasting method is pivotal to creating the balance of extractives present in each product, and therefore is more influential than contact time with wine to find sensory differences among the tank staves during aging.

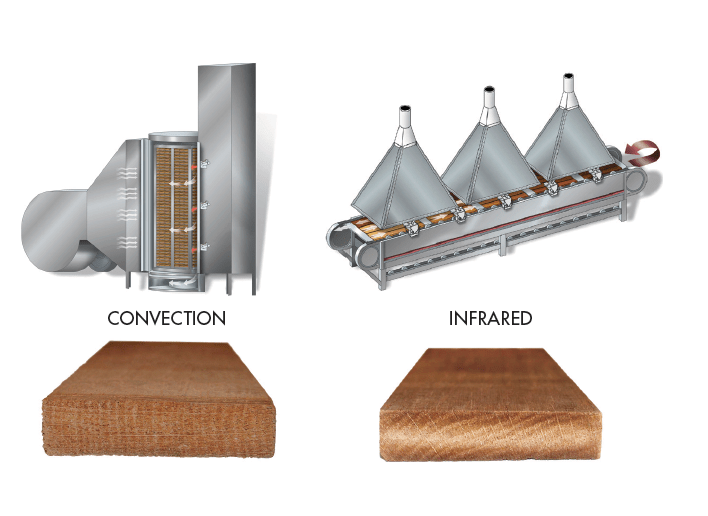

Figure 10: Tank Stave Toasting Methods

Convection: the end result is a uniform, consistent toast; the exterior and interior of the wood will be toasted identically. Infrared: the end result is a gradient of toast, conveying different nuances from the surface to the center of the oak alternative.

COMMERCIAL EXPERIMENT

using 30 Gallon Stainless steel drums at UC Davis with Albariño, Vintage 2013

This experiment was designed to study the impact of dose rate, particle size and contact time. The experiment included using three commercial products with the same toast, Pure2 High Vanilla. This toast was applied to three particle sizes – large chips, cubes and tank staves. These three product types were applied at two dose rates, 3 g/L and 9 g/L. The objective was to better understand the influence of the wine’s sorption speed in the wood products and the optimal concentration of desirable compounds.

- Pure2 High Vanilla Chips at a dose rate of 3 g/L (Chips3g)

- Pure2 High Vanilla Chips at a dose rate of 9 g/L (Chips9g)

- Pure2 High Vanilla Cubes at a dose rate of 3 g/L (Cubes3g)

- Pure2 High Vanilla Cubes at a dose rate of 9 g/L (Cubes9g)

- Pure2 High Vanilla Tank Staves at a dose rate of 3 g/L (TS3g)

- Pure2 High Vanilla Tank Staves at a dose rate of 9 g/L (TS9g)

Samples were pulled weekly for sensory and chemical analyses for 8 weeks.

The samples from each week are labeled in some of the graphs with the abbreviation of the product and dose rate followed of W for week and a number representing the weeks of contact time. (Example: Chips at a dose rate of 3 g/L pulled after 2 weeks of contact time will be labeled as Chips3gw2).

Results and Discussion

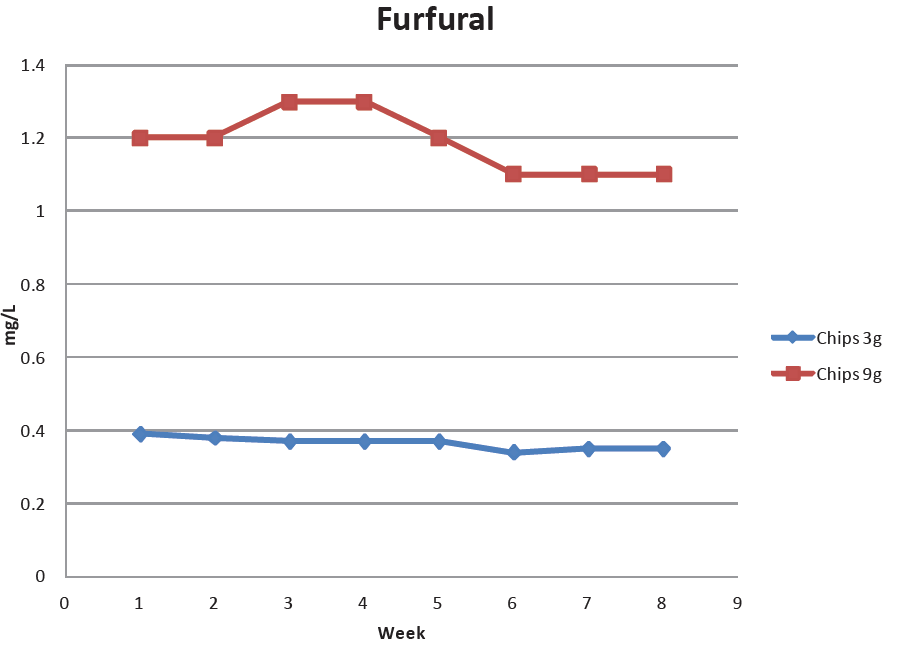

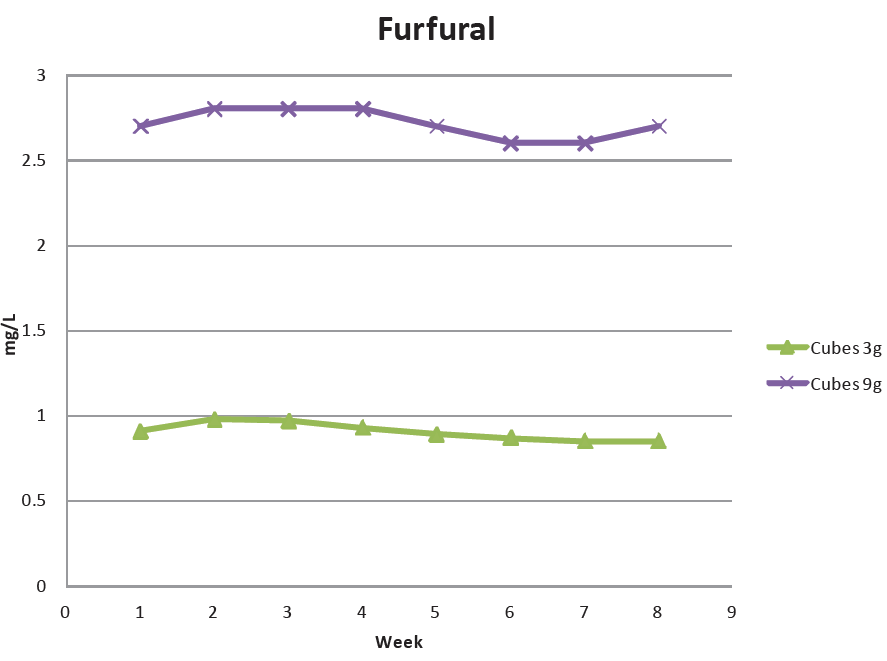

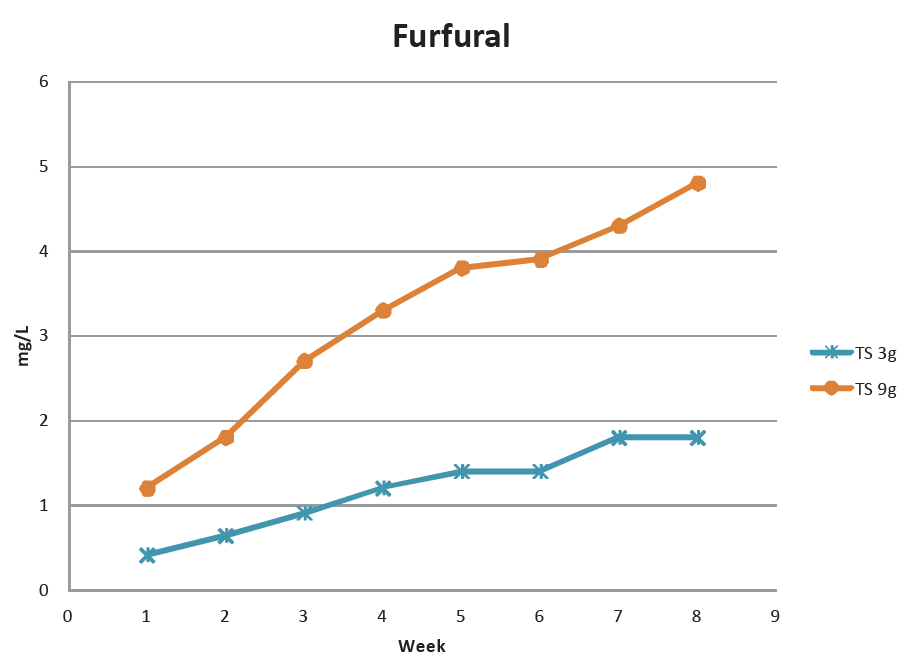

Wine stored in stainless steel containers can get reductive because there is minimal oxygen uptake. Since the stainless steel con drums at UC Davis were stored in the barrel room with a temperature and humidity controlled environment, furfural can reach a maximum extraction early in the process, and in reductive conditions, it can be reduced to furfuryl alcohol. Therefore it can be seen in Figures 11-13 that products with faster sorption of the wine in the wood, such as chips and cubes, have a lower level of furfural after 8 weeks of contact than they did at 4 weeks. For the tank staves on the other hand, the maximum extraction level has not been achieved during this period and the level of furfural is still climbing at 8 weeks of contact time.

Figure 11

Figure 12

Figure 13

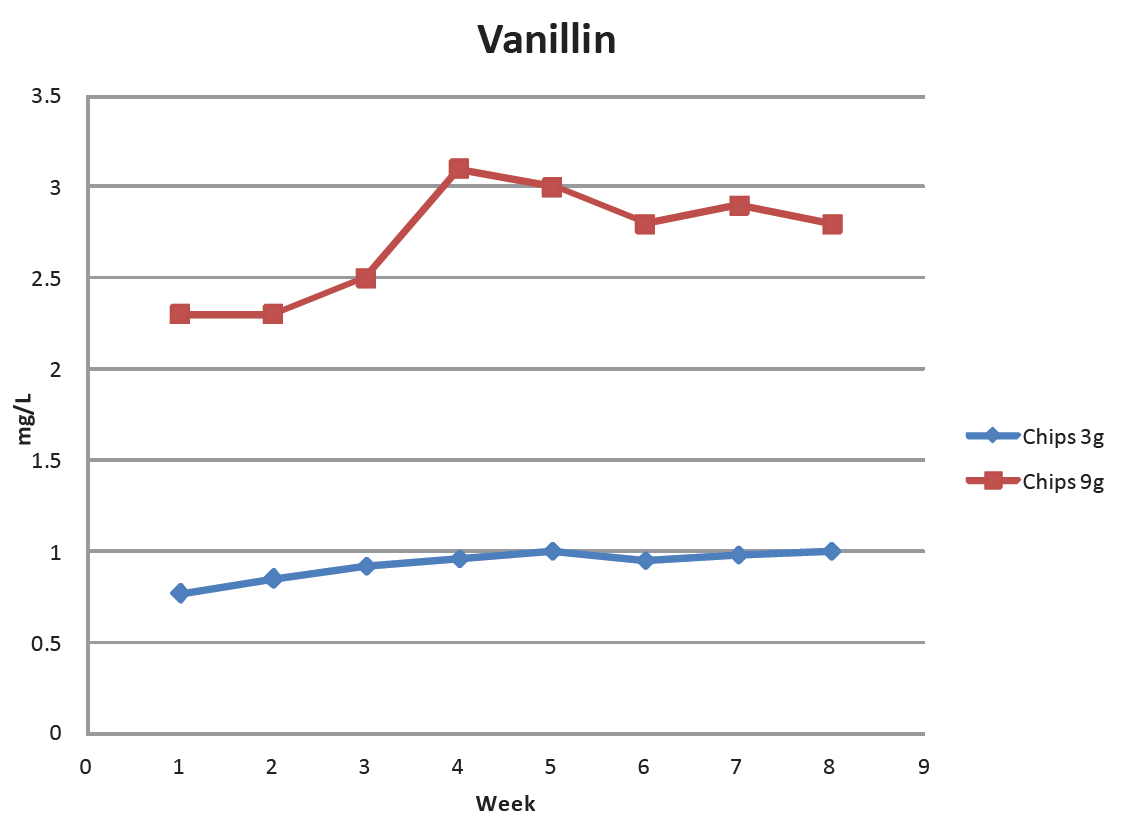

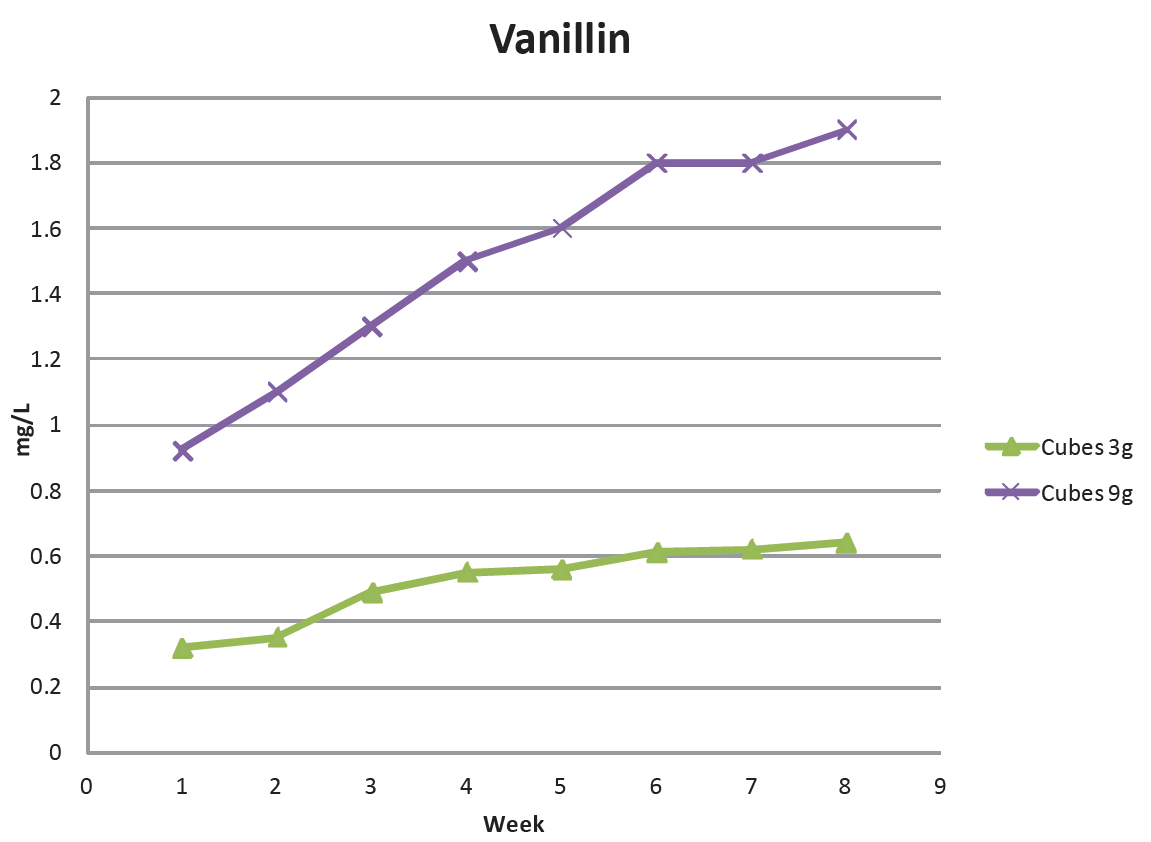

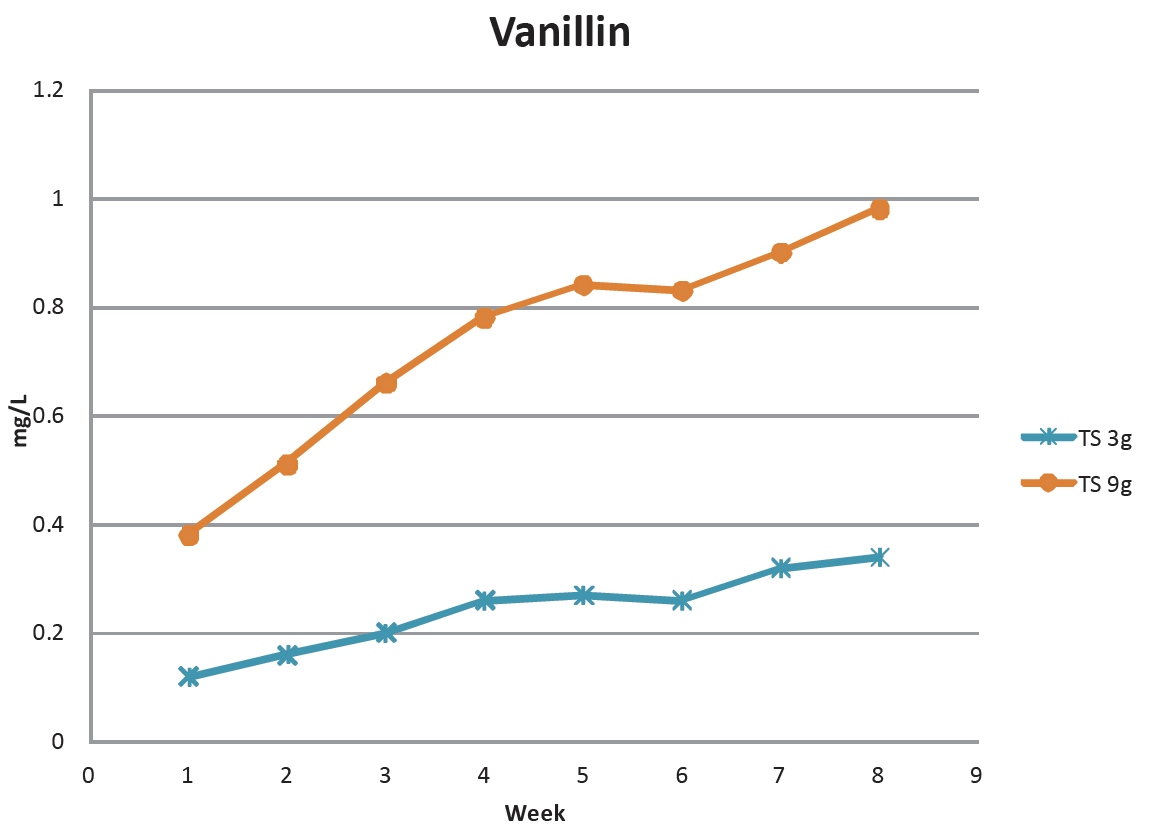

Vanillin reaches a maximum for chips after approximately 4 weeks, but cubes and tank staves take longer because the wine has a slower sorption rate for these products.

Figure 14

Figure 15

Figure 16

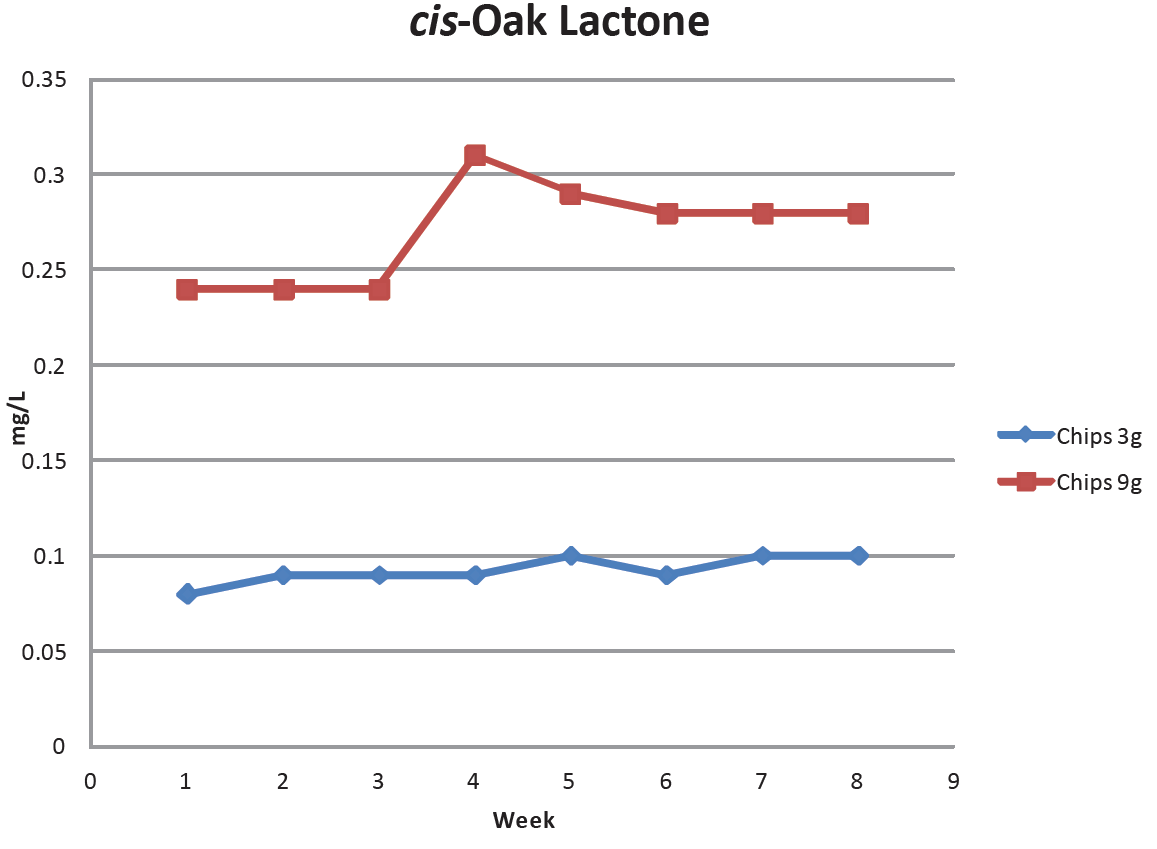

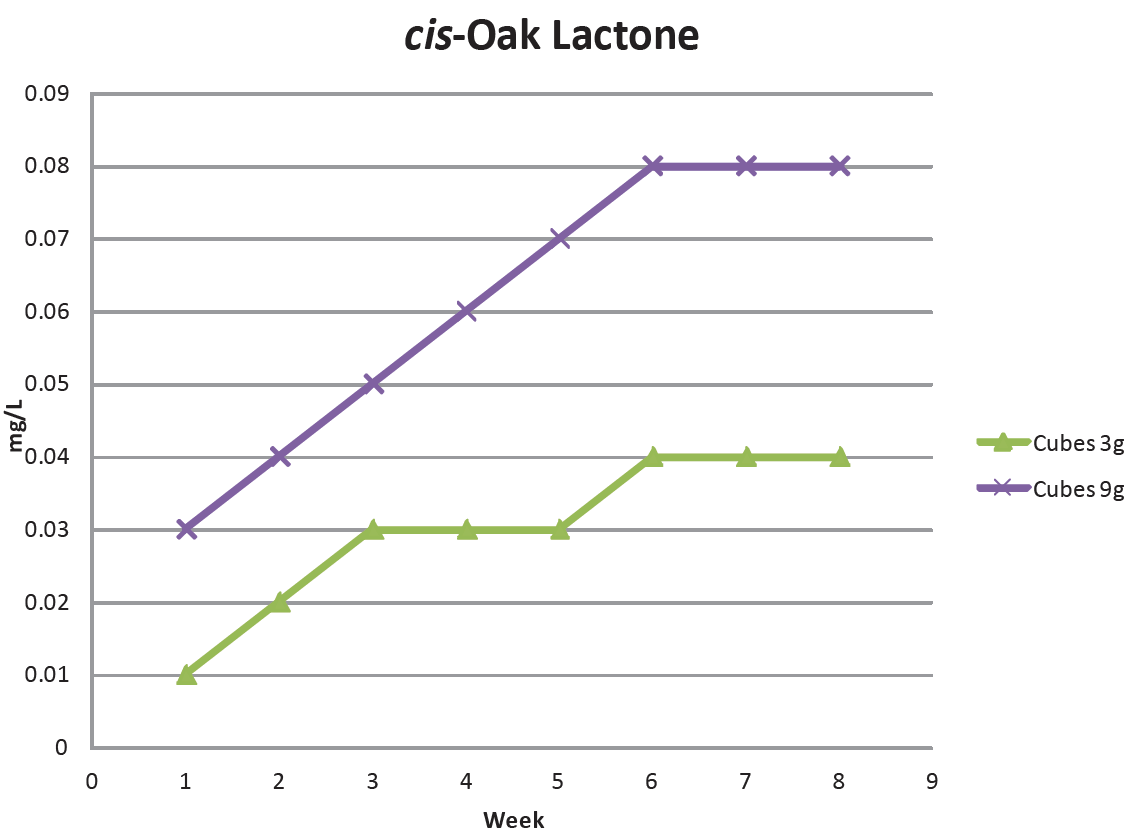

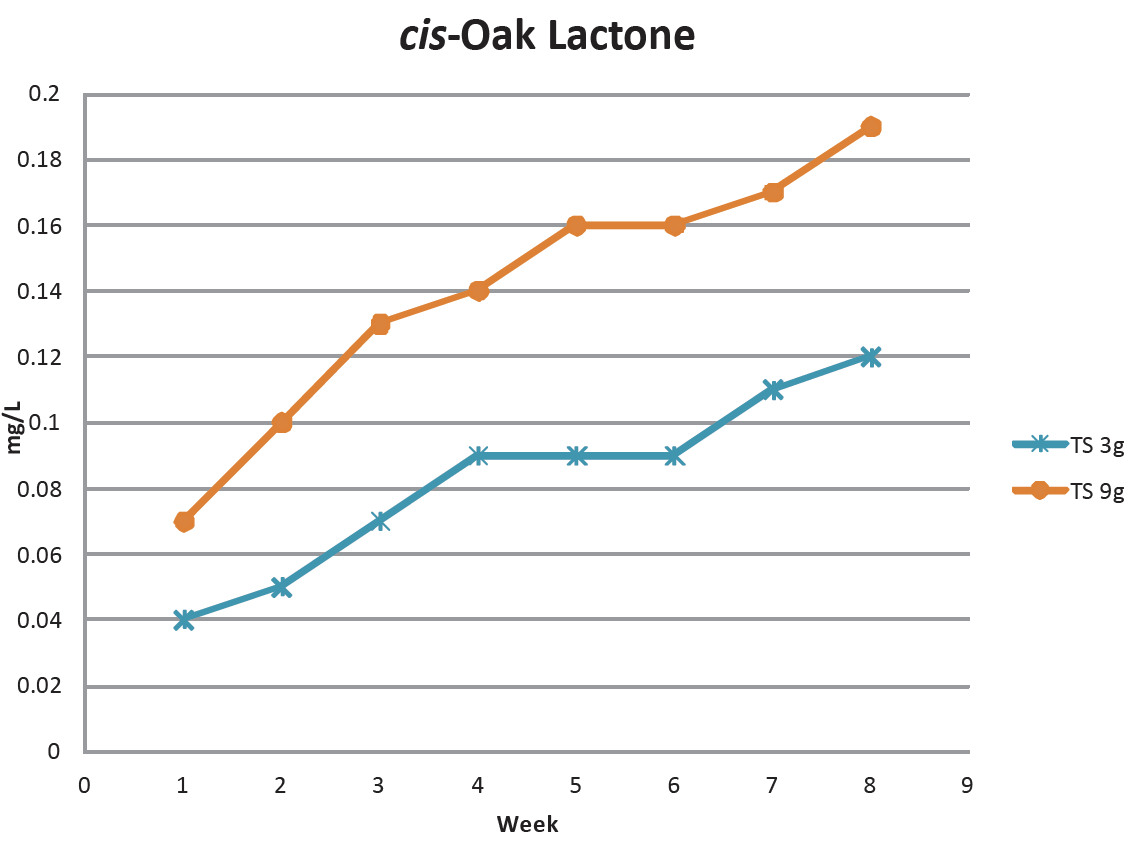

Oak lactones are extracted faster in chips, then cubes and the slowest extraction happens in the tank staves, as shown in Figures 17-19.

Figure 17

Figure 18

Figure 19

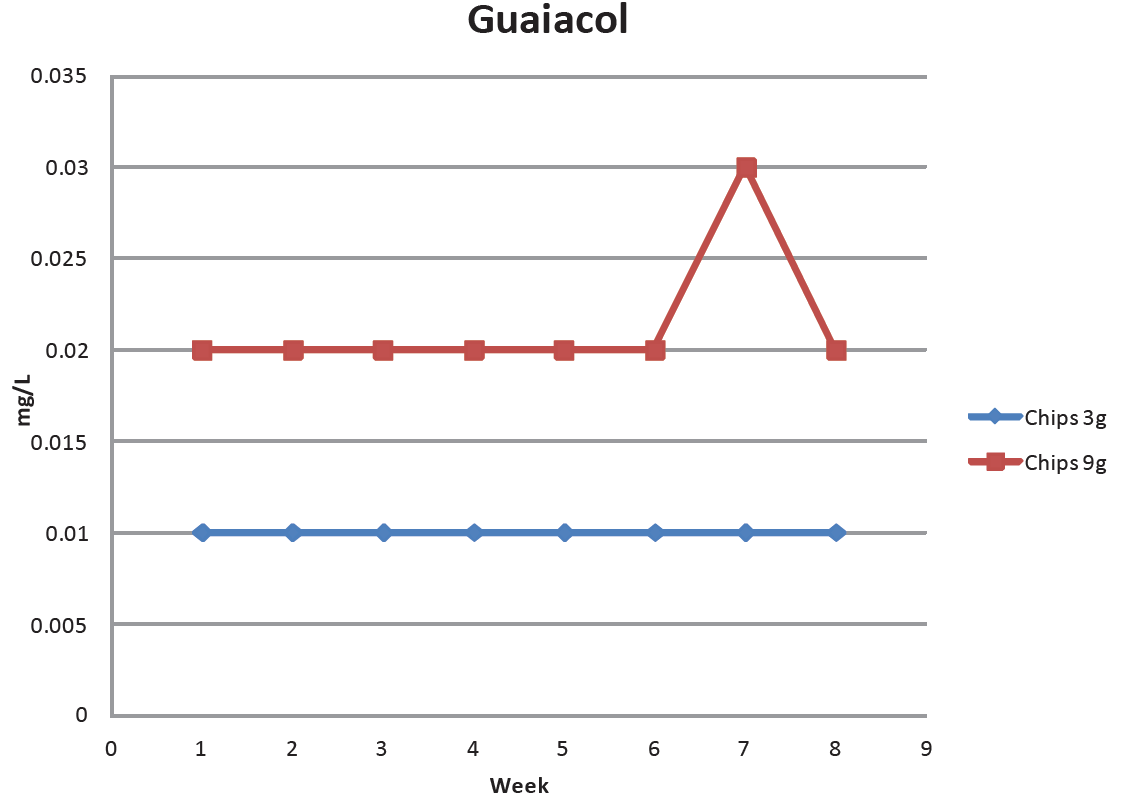

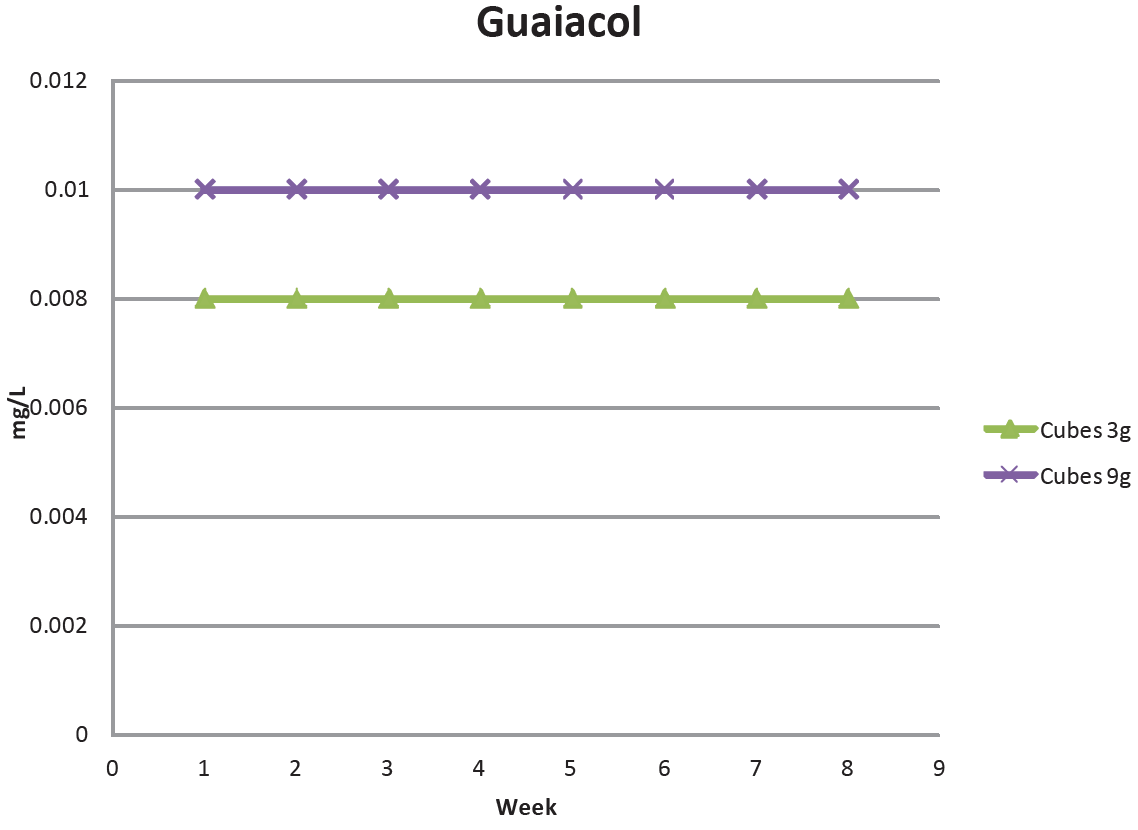

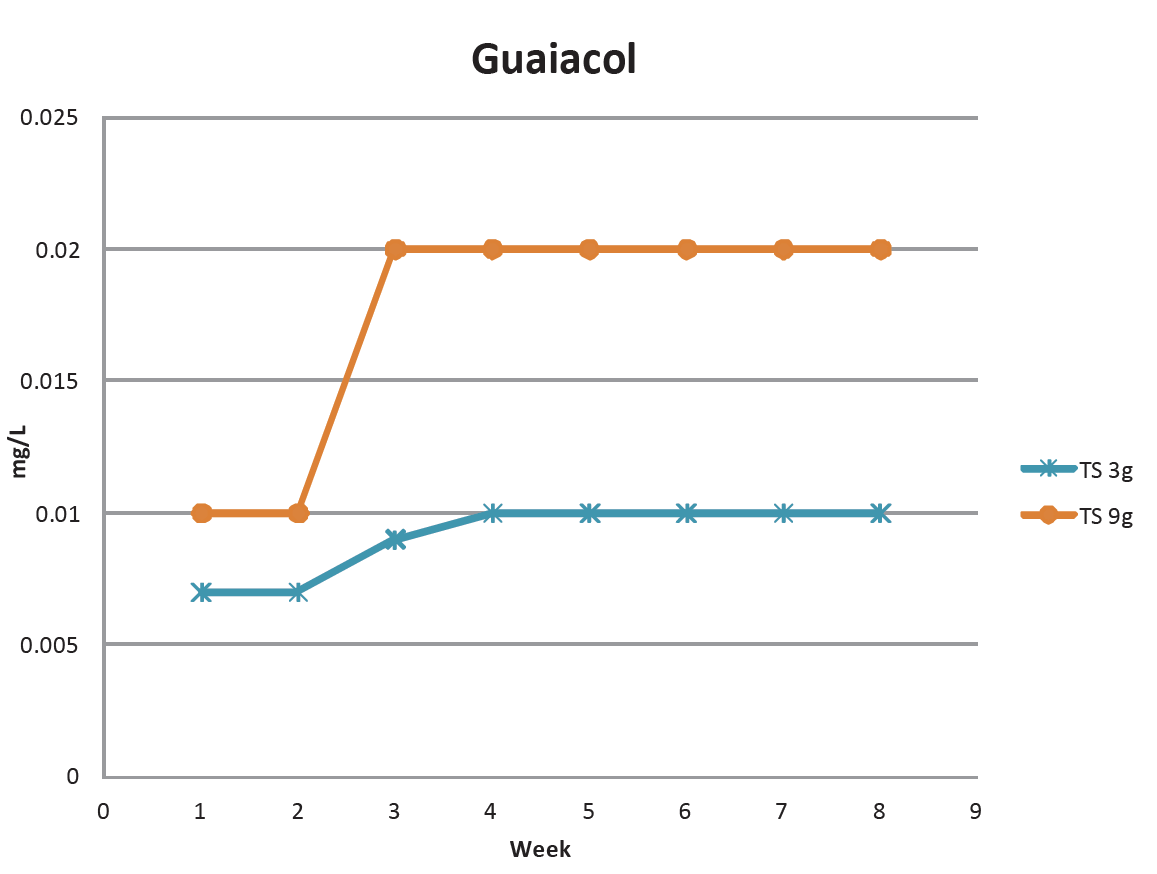

Guaiacol doesn’t change much in concentration after a week of contact time for chips and cubes, but it takes 3 to 4 weeks for the tank staves to reach the maximum and the equilibrium.

Figure 20

Figure 21

Figure 22

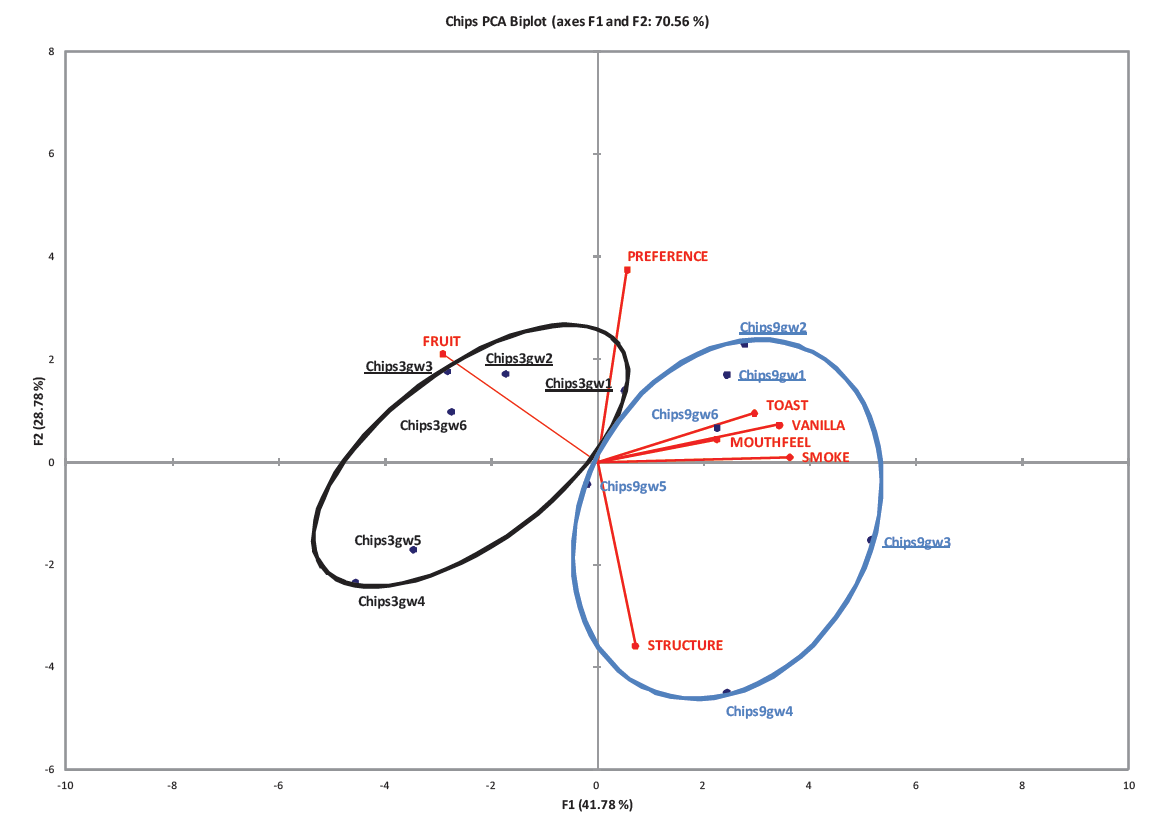

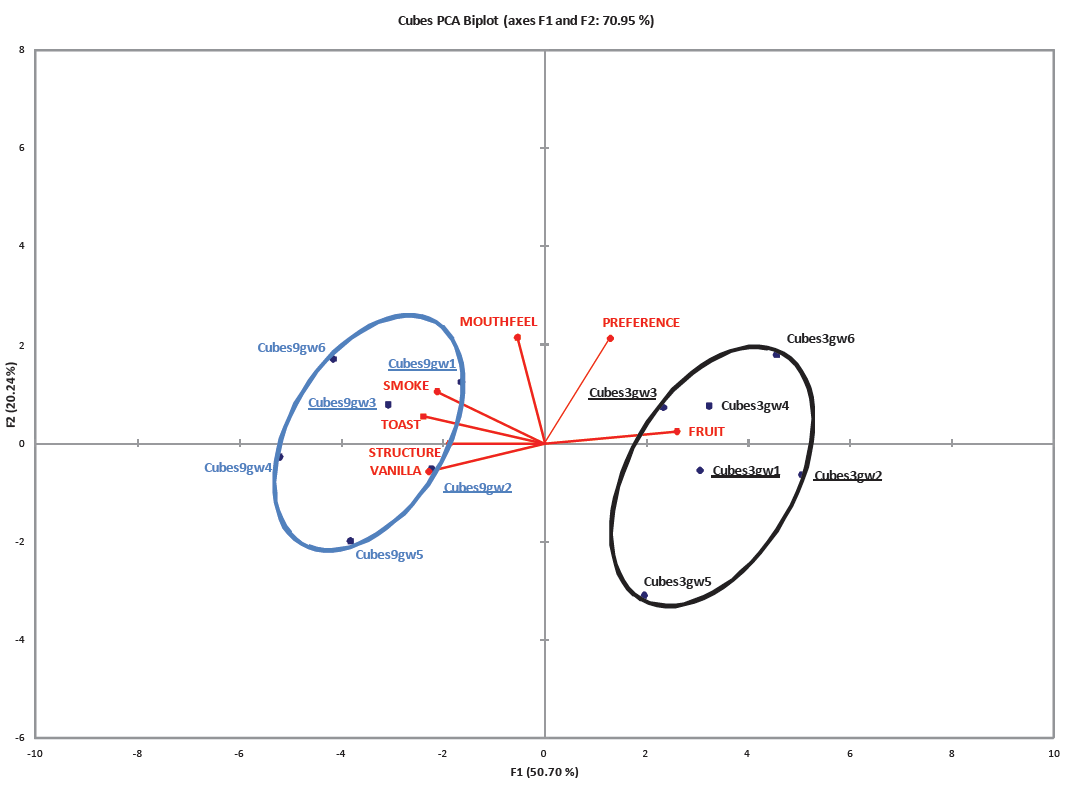

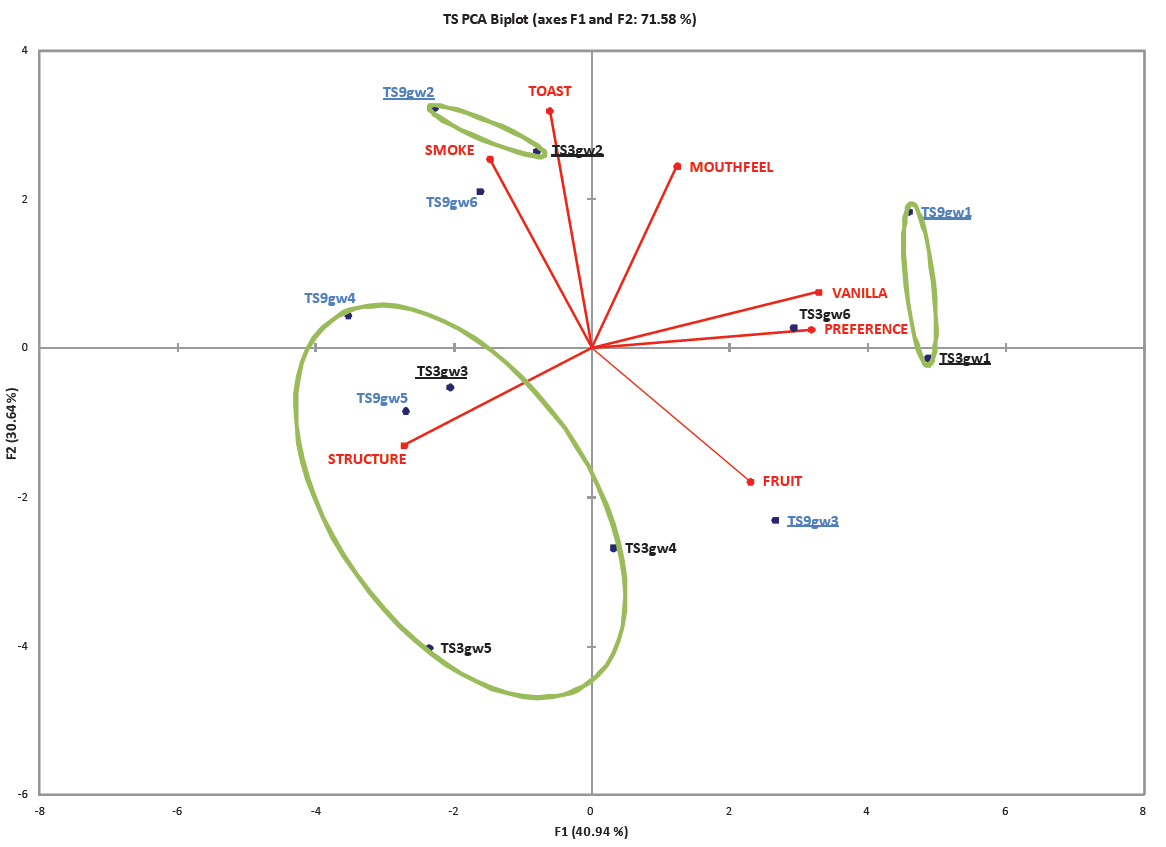

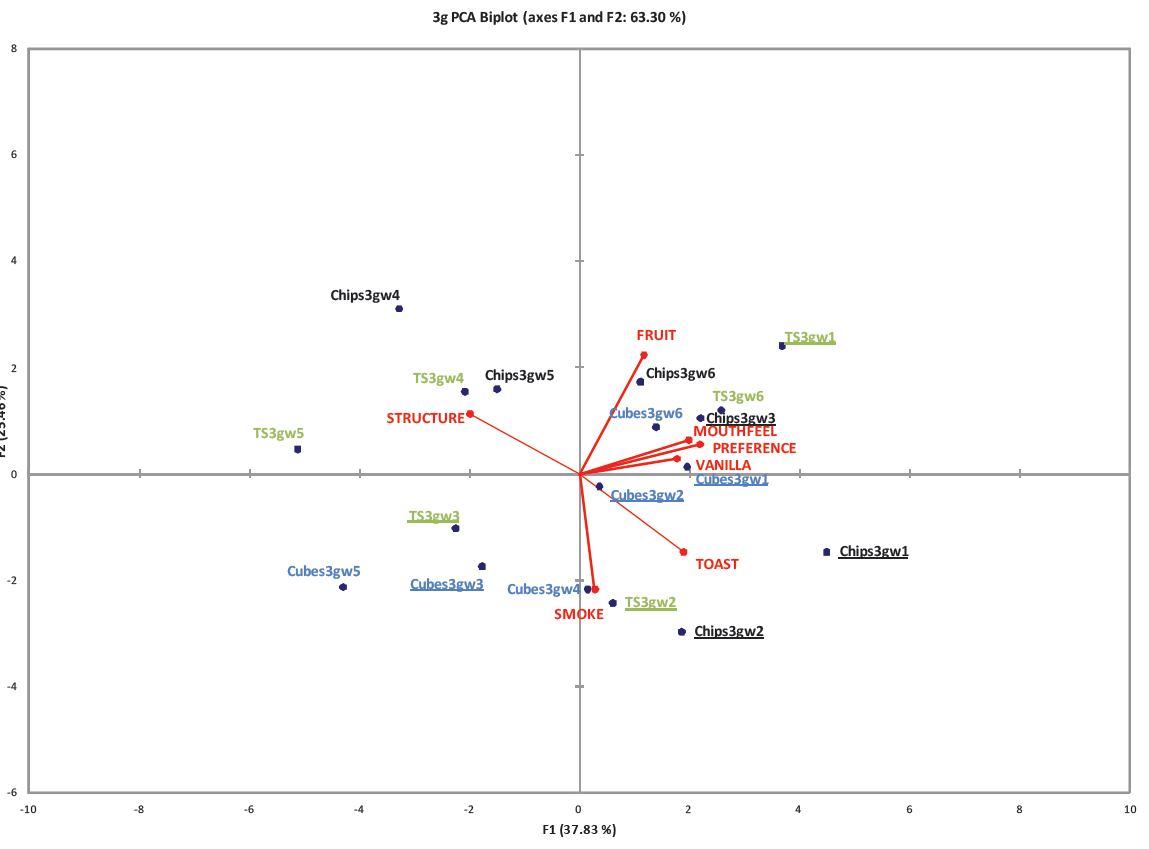

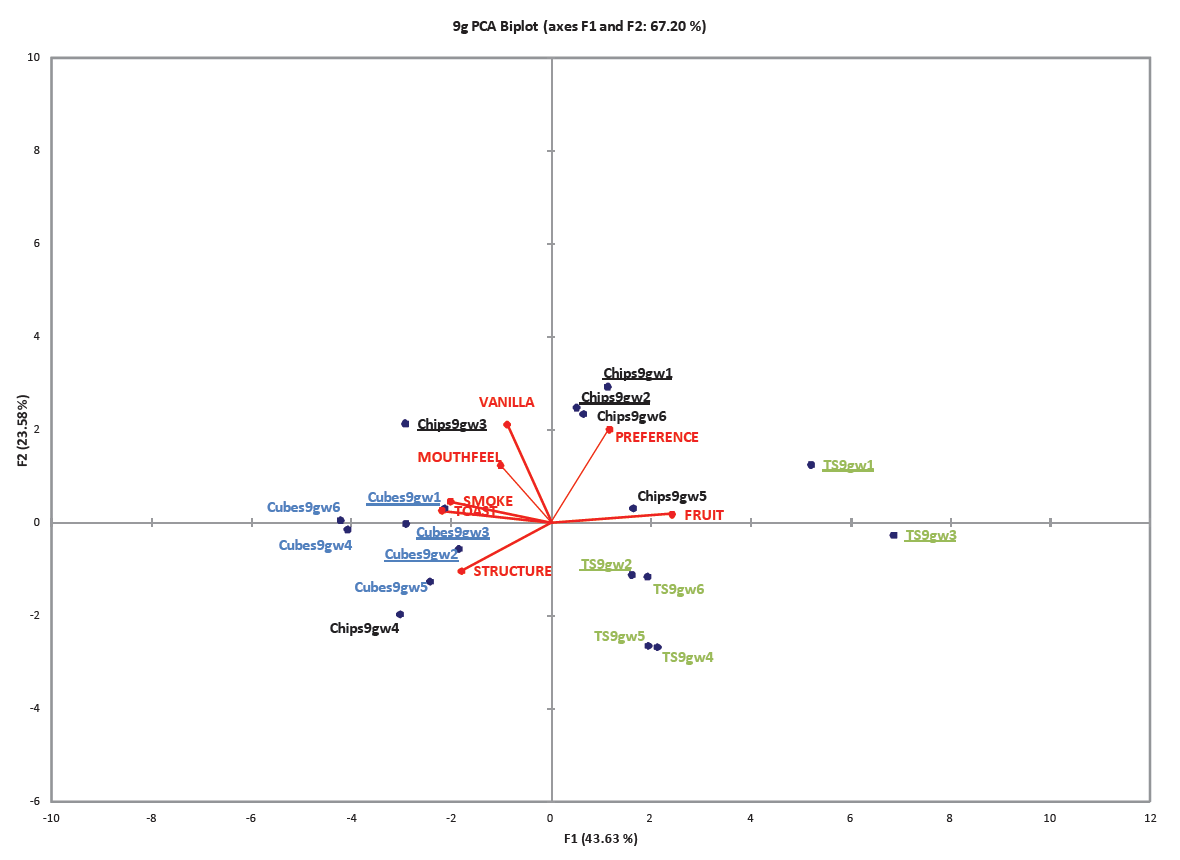

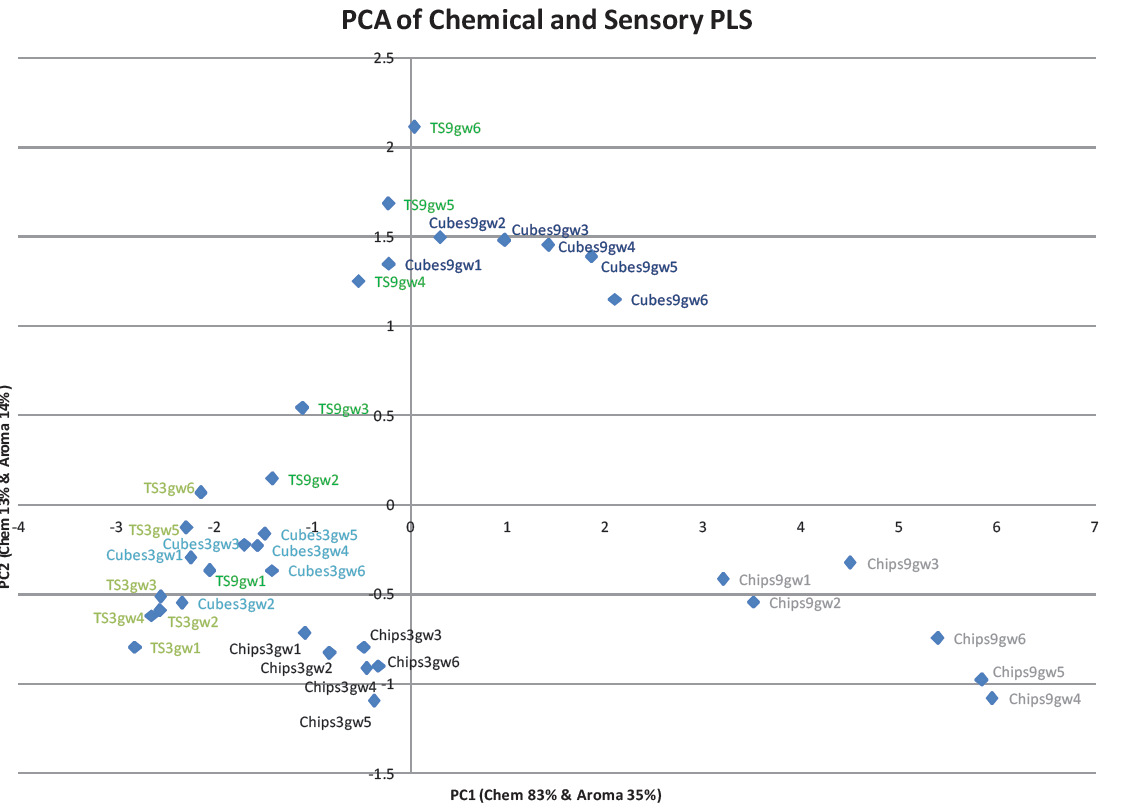

The principal component analysis plots (Figures 23-27) from the sensory evaluation data serve as a helpful reference to understand the effects on contact time, dose rate and particle size.

Figure 23

Dose rate plays an important role in the perception of oak-derived aromas in wine when using chips or cubes. However, the impact of dose rate is less noticeable in tank staves in only 8 weeks because of the slower sorption rates. Most likely, the higher dose rate in tank staves will have an effect after reaching the maximum extraction level for all aromatics and when the equilibrium has been achieved. The higher concentration of some of the compounds is found in the inner layers; it will take few months for the wine to reach the core of the tank staves and for the aromatics to diffuse in the whole volume of wine and equilibrate.

Figure 24

Figure 25

Figure 26

Figure 27

At 3 g/L, contact time and particle size have a lesser effect on aromatic perception, but at 9 g/L, it is obvious the grouping by particle size and

the effect on the sorption kinetics make a difference because of higher concentration of chemical compounds that will be above the threshold of

detection, making easier for the taster to define the aromatic differences.

Figure 28

Conclusions

Balanced extractions will be achieved at different contact times depending on particle size (chips extract faster than cubes, which extract faster than tank staves). Cubes can replace tank staves at shorter contact times when time is limited. For maximum levels of aromatic attributes in wine, high dose rate and short contact time work well, and the oak alternatives will be used only once for this purpose. Second use is possible in another wine at a low dose rate for a longer time. Because the highest concentration of each compound is found at different depths in the wood, and each compound also has a different level of solubility, this is the expected extraction order from toasted oak in wine: Guaiacol-Furfural-Vanillin-Lactone-Tannin. The order of extraction and intensity can vary depending on the wood type, toasting level and type, but this is the guideline of what to expect.

APPLICATIONS

- Replacing tank staves with cubes when time is crucial.

- Higher dose rates in chips for short contact time to maximize the aromatic attributes.

- More contact time will allow further sorption into wood, resulting in more tannins and lactones. o Variables such as heat source, toast type (beginning compound availability) and depth in the wood, as well as type of beverage, will affect the extraction rate and the chemical composition at a given time during the maturation process.

- Dose rate and contact time management will allow optimal aromatic extraction from oak. Consider the extraction order when determining contact time, as you can adjust the length of time to best achieve the target extractives you are wanting to focus on.

- Adding another tool (i.e. enological tannins) for consistency in wine production. The extractions of aroma compounds from oak occur faster than the extraction of the tannins. It could be useful to achieve the desired aromatic profile as soon as possible and correct the tannin content by the use of enological tannins without the need to wait for their extraction from the oak, which might risk a higher concentration than it is desired.